Maintaining and Enhancing Your Garage Door Components

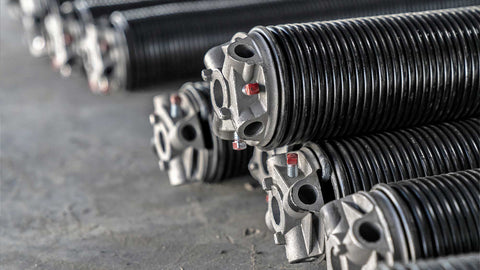

To lengthen the lifespan of your garage door parts, consider using powder-coated springs and hardware. Although this option incurs a higher cost than traditional parts, it offers several advantages.

- Protective Coating: Powder coating provides a protective layer to springs and hardware, reducing corrosion and rust, particularly in humid environments. Additionally, it resists chipping, scratches, fading, and wear.

- Increased Lifespan: The protective coating extends the lifespan of garage door springs and hardware, preventing rust and corrosion build-up, making maintenance easier, and ensuring a longer lifespan.

- Aesthetic Appeal: Powder coating offers a clean, lasting look to garage door springs and hardware, making it ideal for garage spaces used as additional living areas. It also allows for color choices that complement the space or specific projects.

Understanding Garage Door Springs

Comprehending spring engineering is crucial for efficient operations and cost-saving strategies in field service. This insight aims to streamline spring conversions, minimize additional expenses, and ensure accurate replacements on-site, ultimately saving time and money for service providers and customers.

Benefits of Spring Engineering Knowledge

- Understanding spring engineering enables:

- Optimal inventory utilization, reducing extra costs

- Engineering springs for extended-cycle life with increased usage

- Verification of correct springs for overhead doors

- Efficient on-site spring conversion and replacement, optimizing time and costs

Basic Spring Conversions On-Site

When replacing garage door springs, accurate conversion from original dimensions to replacement specifications is essential. Key factors for conversion include Inch Pounds Per Turn (IPPT) and maximum turns to ensure the new spring closely aligns with the original.

Understanding Garage Door Spring Wire

There are four types of spring wire used in garage doors: oil tempered, hard drawn, galvanized, and square. Each type has specific properties and applications that cater to different needs and environmental conditions.

- Oil Tempered Wire: Utilized for manufacturing torsion and extension garage door springs, this wire undergoes a special heat treatment process, providing ideal properties for garage door springs.

- Hard Drawn Springs: Similar to oil tempered springs but with fewer steps and no heat, these are commonly used for extension springs.

- Galvanized Springs: Introduced in the mid-1980s, these springs have a zinc coating to resist corrosion, making them suitable for corrosive environments.

- Square Wire: Used in the manufacturing of garage door torsion springs, it allows for greater energy storage in a smaller area, suitable for specific requirements such as limited shaft space and high-speed roll-up doors with extended cycle life.